| Size (mm) | Installed Length | Material Type | Temperature Limits °C | Part Number |

|---|---|---|---|---|

| 32 | 130 | Nylon Reinforced EPDM | -10 – 90 | DST/032/PN16/6 |

| 40 | 130 | Nylon Reinforced EPDM | -10 -90 | DST/040/PN16/6 |

| 50 | 130 | Nylon Reinforced EPDM | -10 – 90 | DST/050/PN16/6 |

| 65 | 130 | Nylon Reinforced EPDM | -10 – 90 | DST/065/PN16/6 |

| 80 | 130 | Nylon Reinforced EPDM | -10 -90 | DST/080/PN16/6 |

| 100 | 130 | Nylon Reinforced EPDM | -10 – 90 | DST/100/PN16/6 |

| 125 | 130 | Nylon Reinforced EPDM | -10 – 90 | DST/125/PN16/6 |

| 150 | 130 | Nylon Reinforced EPDM | -10 – 90 | DST/150/PN16/6 |

EXCO D-Flex Flexibles are installed to absorb vibration and noise levels caused by “Plant” upon which they are fitted. These are suitable for use on systems carrying Chilled & Heating Water. Please see above for temperature & pressure limits.

EXCO D-Flex units are not suitable for use with Potable Water, Water with Oil additives, Compressed Air and Food Applications.

EXCO D-Flex Untied units should not be installed on pumps located on inertia bases.

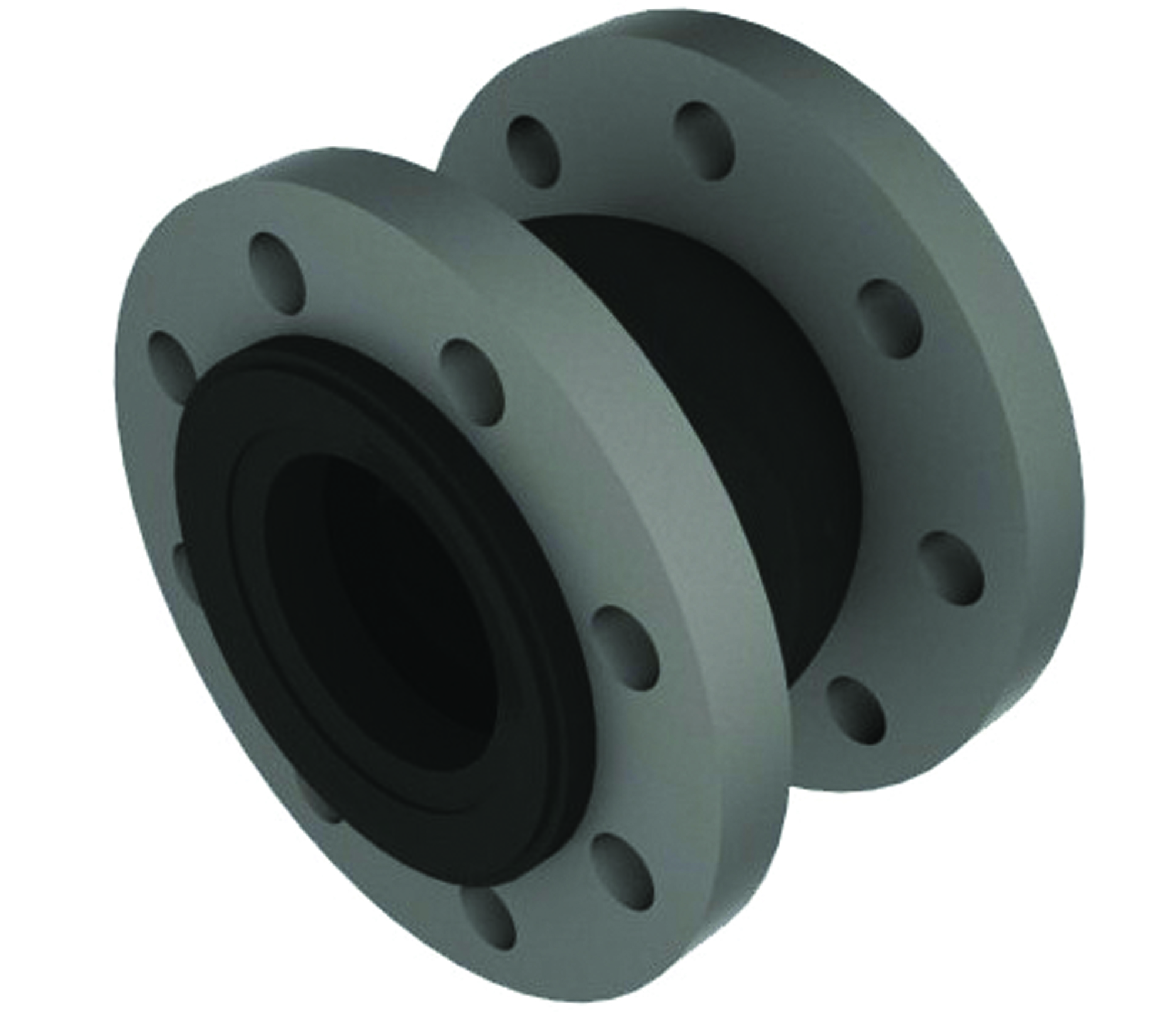

EXCO D-Flex units are manufactured from spherical moulded EPDM, which is a soft compound to offer a high isolation efficiency and high noise absorbing properties.

The units are a full bore thus removing pressure drop problems. The EPDM rubber is nylon re-inforced, and has a steel wire re-inforced collar.

Flanges BZP coated carbon steel PN16.

D-Flex units have a 10 year design life when used on LTHW systems.

EXCO D-Flex units are stamped with Origin of Manufacture, Date of Manufacture, Batch Number and Size.

Please note no torsion forces should be applied to these units.

EXCO Ltd also supply DIN 4809 Approved Pump Flexibles. Please contact our sales Office for further information.