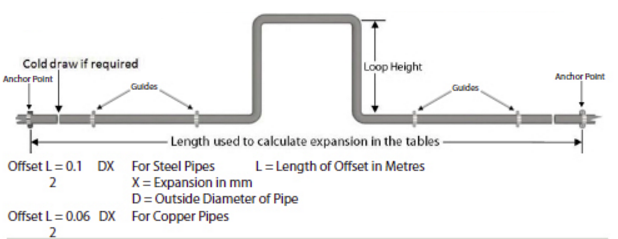

If the use of expansion devices is not suitable for the application, you may be able to utilise expansion loops to take up the thermal expansion of the pipework. Loops should always be positioned in the middle of a pipe run, with anchors at the end of each run.

Loops are often useful on a drop rod system as axial expansion devices cannot be used on such a system. If you design a loop into a pipework system, we strongly recommend the use of EXCO Ball Hangers to aid movement.

| Table Showing Single Offset For Steel Pipes (Without Cold Draw) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Expansion | Pipe Nominal Bore | |||||||||||

| x | 15nb | 20nb | 25nb | 32nb | 40nb | 50nb | 65nb | 80nb | 100nb | 125nb | 150nb | 200nb |

| 1 mm | 0.32 | 0.36 | 0.41 | 0.46 | 0.49 | 0.55 | 0.62 | 0.67 | 0.75 | 0.84 | 0.92 | 1.05 |

| 3 mm | 0.56 | 0.64 | 0.71 | 0.79 | 0.85 | 0.95 | 1.07 | 1.15 | 1.31 | 1.45 | 1.59 | 1.82 |

| 5 mm | 0.72 | 0.82 | 0.92 | 1.02 | 1.09 | 1.22 | 1.38 | 1.49 | 1.69 | 1.87 | 2.05 | 2.35 |

| 10 mm | 1.02 | 1.16 | 1.30 | 1.45 | 1.55 | 1.73 | 1.94 | 2.11 | 2.39 | 2.65 | 2.89 | 3.31 |

| 15 mm | 1.25 | 1.50 | 1.59 | 1.77 | 1.89 | 2.12 | 2.39 | 2.58 | 2.92 | 3.24 | 3.55 | 4.06 |

| 20 mm | 1.45 | 1.64 | 1.84 | 2.05 | 2.19 | 2.45 | 2.76 | 2.98 | 3.38 | 3.74 | 4.09 | 4.69 |

| 30 mm | 1.77 | 2.01 | 2.26 | 2.51 | 2.68 | 3.00 | 3.38 | 3.65 | 4.13 | 4.58 | 5.01 | 5.74 |

| 40 mm | 2.05 | 2.32 | 2.61 | 2.89 | 3.09 | 3.46 | 3.89 | 4.22 | 4.77 | 5.29 | 5.79 | 6.63 |

| 60 mm | 2.50 | 2.84 | 3.19 | 3.54 | 9.79 | 4.24 | 4.77 | 5.17 | 5.58 | 6.48 | 7.09 | 8.12 |

| 80 mm | 2.89 | 3.29 | 3.69 | 4.09 | 4.38 | 4.89 | 5.11 | 5.97 | 6.75 | 7.48 | 8.19 | 9.93 |

| 100 mm | 3.24 | 3.67 | 4.12 | 4.58 | 4.89 | 5.48 | 6.16 | 6.67 | 7.54 | 8.37 | 9.17 | 10.48 |

| Table Showing Single Offset For Copper Pipes (Without Cold Draw) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Expansion | Pipe Nominal Bore | |||||||||||

| x | 15nb | 22nb | 28nb | 35nb | 42nb | 54nb | 67nb | 76nb | 108nb | 133nb | 159nb | 219nb |

| 1 mm | 0.16 | 0.19 | 0.22 | 0.25 | 0.27 | 0.31 | 0.35 | 0.37 | 0.44 | 0.49 | 0.53 | 0.63 |

| 3 mm | 0.28 | 0.34 | 0.38 | 0.43 | 0.48 | 0.54 | 0.60 | 0.64 | 0.76 | 0.85 | 0.92 | 1.08 |

| 5 mm | 0.56 | 0.44 | 0.50 | 0.56 | 0.61 | 0.69 | 0.77 | 0.83 | 0.98 | 1.09 | 1.19 | 1.40 |

| 10 mm | 0.59 | 0.63 | 0.71 | 0.79 | 0.87 | 0.98 | 1.09 | 1.17 | 1.39 | 1.55 | 1.69 | 1.98 |

| 15 mm | 0.63 | 0.77 | 0.87 | 0.97 | 1.06 | 1.21 | 1.34 | 1.43 | 1.71 | 1.89 | 2.07 | 2.43 |

| 20 mm | 0.73 | 0.89 | 1.00 | 1.12 | 1.22 | 1.39 | 1.55 | 1.65 | 1.97 | 2.19 | 2.39 | 2.81 |

| 30 mm | 0.90 | 1.09 | 1.23 | 1.37 | 1.51 | 1.71 | 1.90 | 2.03 | 2.41 | 2.67 | 2.93 | 3.43 |

| 40 mm | 1.04 | 1.26 | 1.42 | 1.59 | 1.73 | 1.97 | 2.19 | 2.34 | 2.79 | 3.09 | 3.38 | 3.97 |

| 60 mm | 1.27 | 1.54 | 1.74 | 1.94 | 2.12 | 2.41 | 2.69 | 2.86 | 3.42 | 3.79 | 4.14 | 4.86 |

| 80 mm | 1.47 | 1.77 | 2.01 | 2.24 | 2.46 | 2.78 | 3.11 | 3.31 | 3.94 | 4.38 | 4.78 | 5.62 |

| 100 mm | 1.64 | 1.99 | 2.24 | 2.51 | 2.75 | 3.12 | 3.47 | 3.69 | 4.41 | 4.89 | 5.35 | 6.28 |

Cold draw can be used if the size of the loop cannot be accommodated. The rate of cold draw is normally 50% of the total movement. If the pipework is suspended using drop rods, it would be advisable to use EXCO Ball Hangers to reduce stresses as the pipework moves.